Linear Symbologies

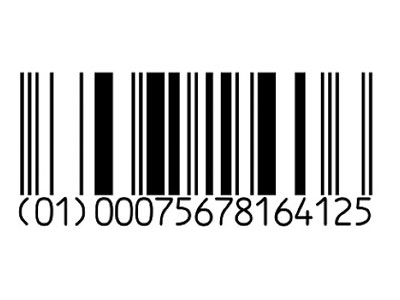

Linear symbologies can be classified mainly by two properties, Continuous vs. discrete & Two-width vs. many-width.

Continuous vs. discrete:

Characters in continuous symbologies usually abut, with one character ending with a space and the next beginning with a bar, or vice versa. Characters in discrete symbologies begin and end with bars; the intercharacter space is ignored, as long as it is not wide enough to look like the code ends.

Two-width vs. many-width

Bars and spaces in two-width symbologies are wide or narrow; the exact width of a wide bar has no significance as long as the symbology requirements for wide bars are adhered to (usually two to three times wider than a narrow bar). Bars and spaces in many-width symbologies are all multiples of a basic width called the module; most such codes use four widths of 1, 2, 3 and 4 modules.